GMOS / bHROS Fibre Connection

M. F. Blanken (ING), G. Talbot (ING), M. Aderin (UCL)

Over

the last year (2002–2003) ING was subcontracted by University College London

(UCL) to produce a module of 18 science fibres for the bHROS instrument,

one of the instruments on the Gemini South telescope.

bHROS is a high-resolution (ℜ=150,000) prism cross dispersed echelle

spectrograph, situated in the pier of Gemini-South. It is fed by optical

fibres mounted on the GMOS instrument located at the Cassegrain focus of

the telescope. bHROS will have the highest spectral resolution among the

optical spectrographs currently being designed and built for 8–10m class

telescopes.

The optical fibre connection between GMOS and bHROS consists of 18 fibres;

9 fibres with a 120µm core diameter and 9 fibres with a 160µm

core diameter. Both types of fibre had to be ground and polished at both

ends. The GMOS end also had to be mounted and aligned in an optical assembly

(a body plate). 10 fibres of each type were delivered by UCL to the ING

out of which 9 of each were to be used for science. The 10th fibre of both

types was manufactured in case of any breakage.

|

|

.

|

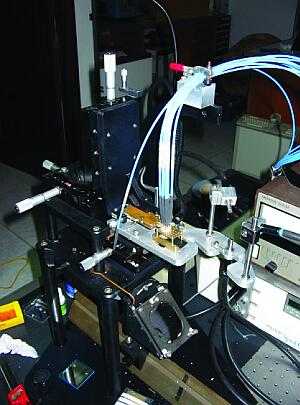

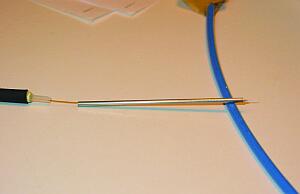

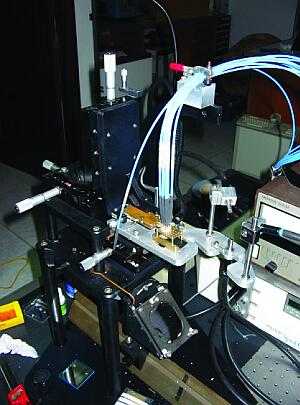

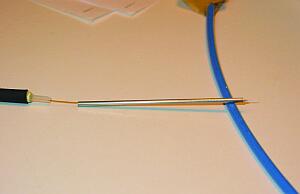

| Figure 1 (left). Fibre grounding

and polishing [ JPEG | TIFF

]. Figure 2 (top right). Fibres in body plate gluing [ JPEG | TIFF ]. Figure 3

(bottom right). Metal tube gluing [ JPEG | TIFF ]. |

The first stage after receiving the fibres was cutting them to the desired

length. After this metal tubes were glued over the fibre ends to make the

grounding, polishing and handling easier. The metal tubes were also connected

to the outer PTFE sleeve of the fibre, using heat shrinks, to give extra

strength and reduce the risk of breaking. Both ends of the fibres were ground

and polished to a flatness of <¼ of a wavelength (632nm).

The body plate for the GMOS end consists of 18 sapphire ball lenses of

two sizes (3mm and 4mm diameter) and 18 silica optical windows (3mm diameter,

300µm thick and 4mm diameter, 400µm thick). The balls and the

windows were glued in the body plate using UV-optical curing glue. Before

the fibres were aligned in the body plate a throughput test was done to

check the relative transmission of the 20 fibres. The best 18 fibres were

aligned on top of the silica windows and the sapphire ball lenses in the

body plate. The alignment was done using a target that simulates the Gemini

telescope pupil (fibre positioning tolerances were 0.02mm). After the alignment,

the fibres were glued in the body plate by using the UV-optical curing glue

and super glue.

After the polishing, aligning and gluing the fibres were sent to the

UK for installation of the optics for the bHROS end. The fibres are now

complete and are waiting to be installed between GMOS and the bHROS instruments

in Chile. bHROS will be fully integrated with the telescope in 2004.

ING is experienced in fibre work after making several successful fibre

projects. One project in particular, “Small fibres” consisted of 160 fibres

with a core diameter of 90µm for the Autofib2 (robotic positioner)/

WYFFOS (optical spectrograph) commissioned in July 2001 (see also

ING Newsl., 4, 26 and

ING Newsl., 5, 19 for more information

and first light report). The procedures and experience of the “Small fibres”

project were used in the GMOS/bHROS project. ING is actively looking for

more fibre work from external institutes for the future.

For more information on the GMOS/ bHROS project please visit the following

sites:

Gemini South telescope:

http://www.gemini.edu/

HROS project page:

http://www.osl.ucl.ac.uk/hros/new/fm-index.html.

¤

Email contact: Maarten

Blanken (

mfb@ing.iac.es)